CNC simulation and control software for milling machine ![]()

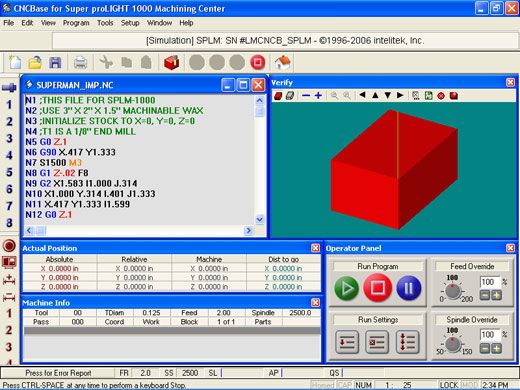

The software for simulation and control is CNCBASE, which is a Windows based CNC control software package for programming and operating Intelitek’s CNC machines. It allows users to control and monitor Intelitek’s CNC machines and to write, edit and run NC part programs.

A screenshot of CNCBase is shown below.

It accepts standard Fanuc-compatible EIA RS274D G & M codes that CNC machines recognize. In addition, it supports absolute and incremental programming, metric and English units, programmable tool offsets and cutter compensation, canned cycles for drilling and boring, etc. It also provides a quick verification of G & M codes to ensure correct and complete syntax during program editing as well as a 2D graphic verification of the tool path.

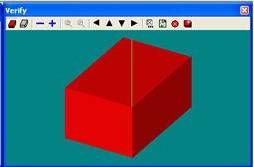

A screenshot of graphical verification of the part program is shown below.

It provides interfaces for manual hardware control such as movement along each axis at customized speed and step settings, spindle activation and speed control, and movement control from dialog box and keyboard as shown below.

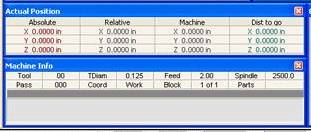

It also provides a real-time data display of current hardware setup, including cross-slide and tool positions, tool in use, machining parameters (feed rate, spindle speed, depth of cut), home switches' status and position errors, hardware status (shield open or closed, robot input), program execution, including block being executed and program run time, etc as shown below.

It also offers icon toolbars for frequently used commands and operations such as tool change and program verification and run as shown below.

![]()

It offers two operating modes namely, Online mode in which CNCBase communicates with the controller and simulation software and Simulation mode in which CNCBase communicates with simulation software.

Click here to refer to the user guide on programming of CNC machine using CNCBase.

The following are detailed specifications of Scorbase Robot program

| Communication with the robot controller over USB channel. |

| Full support and real time status display of robot,gripper and peripheral. |

| Scorbase program run time position manipulation. |

| Interrupt programming for handling responses to changes in digital input status. |

| The Cartesian Coordinate System(X,Y,Z,Pitch,Roll)is also used. |

| Visual Basic Script language integration to realize. |

| Extensive Variable Programming. |

| Multitasking capability with 100 concurrent running programs. |

| Saving and loading projects. |

The instruction in this page are for Scorbase only. If Robocell software is used go to here

The following are detailed specifications of the cnc milling machine

Power |

1 hp, 746W |

Motor type |

1 hp, 746W DC permanent magnet |

| Speed range | 0-3000 RPM |

| Throat | 5.5" (139 mm) |

Axis Travel |

X axis: 304 mm |

Feed rate |

2-1905 mm/min |

| Rapid traverse | 1905 mm/min |

| Stepper motors | 97 Ncm, 200 steps/rev |

| Nickel-plated table | 436 mm x 127 mm |

Repeatability: |

0.0127 mm |

| Resolution 1/2 step: | 0.0032 mm |